Partner for manufacturing and testing prototypes

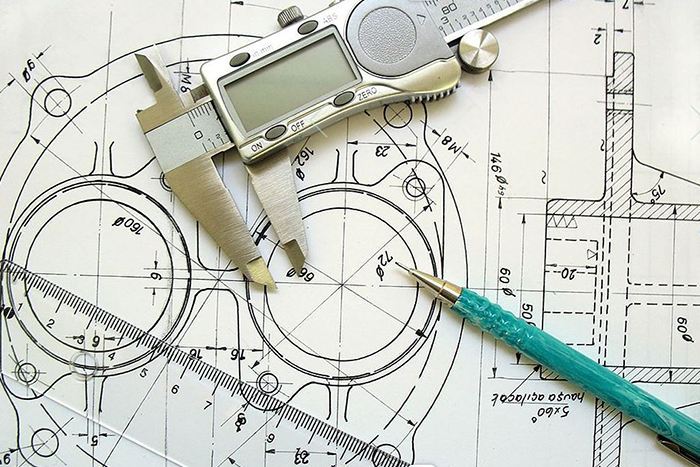

Defour quickly implements high-quality prototypes. One of the most important aspects of agile and functional product development is the production and testing of the first prototype of the product in other words a model of the product.

In the prototype phase, Defour finds out possible problems with the product and we make the necessary changes to the product or the manufacturing process. We use 3D printing methods, mould techniques and machining in prototyping.

Checking the efficiency of the production process

Prototype means the first version of product development that has not yet been manufactured. When creating a prototype, the functionality of the technical implementation of the concept is studied. The second stage is to make sure product’s the manufacturability and the functioning of the production process. 0-series means the trial production series in which details like production costs are refined further.

If necessary, we manufacture several prototypes at different stages of product development. Usually in the prototype phase, the product development is established so the designs are being put into practice and the implementation phase can start.

Defour's product development is comprehensive, which also includes the management and administration of the product development process. During the process, all plans and prototypes made are analysed and the project is documented.

We use 3D printing that enables fast and flexible production of prototypes. A prototype can involve an entire product or just a part like a subassembly of a product. Manufacturing a 3D printed prototype is also an inexpensive solution. However, printing is not possible for all prototypes, in which case we use mould or machining technology to help.

Ask more about product development or prototyping!